Hello list,

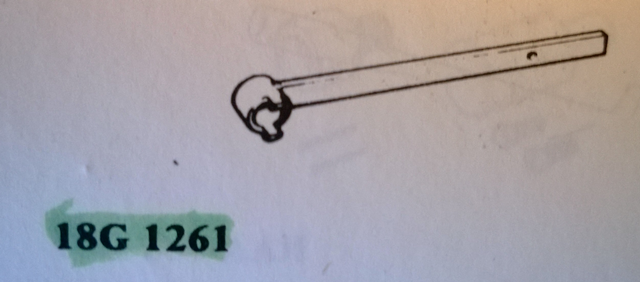

Can anyone advise what the (Leyland Specialist) tool looks like that removes the end plug holding in the steering pinion on a manual Tr7 steering rack?

It's the part labelled "end plug" in fig. 4 of this diagram:

http://vintage.mitchell1.com/PClubData/chassis/chis78/V2I7810106.pdf

My Haynes manual just calls it the "specialist tool", and my TR8 manual naturally doesn't discuss the manual rack...

Thanks in advance.

Craig

TR7V8