<blockquote id="quote"><font size="1" face="Century Gothic, Verdana, Arial, Helvetica" id="quote">quote:<hr height="1" noshade id="quote"><i>Originally posted by DNK</i>

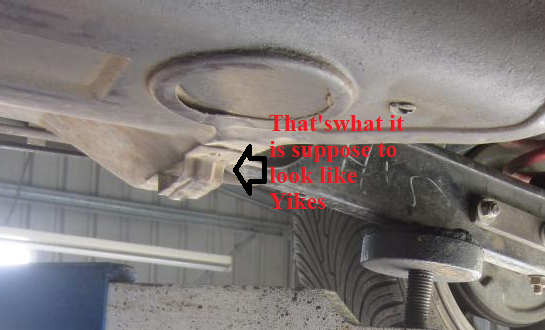

Ron- In that pic with the back locations.There is a crumpled,flattened or something piece of metal.

What was that I see it in mine too?

<hr height="1" noshade id="quote"></font id="quote"></blockquote id="quote">

I read somewhere that bracket was used as a tie down point used during shipping. most are caved in as they have been used as a support point at some time in their lives. Not meant for that.

Good point made that you have to be very careful with support points when removing heavy parts like engine, trans, rear axle.

I've only had one incidence. When jacking up on side of the Integra on the jack point the jack was on rough cement driveway and the wheels couldn't move over it as the car was raised, jack slipped off jack point and rested on car floor denting it. I now have a plate steel for the jack wheels have something smooth to turn on. Never in any danger of course as never get near the car unless it's on jack stands. If supporting on a new point or new car always give the heave ho to make sure it's not going anywhere.

- - -TR7 Spider - - - 1978 Spitfire- - - - 1976 Spitfire - - 1988 Tercel 4X4 - Kali on Integra - 1991 Integra - Yellow TCT

<font color="red"><b>My two 1980 Wedges...</b></font id="red">

<font color="red"><b>My two 1980 Wedges...</b></font id="red">