Ah yes you are not the first person driven to drink by a TR and I am sure you wont be the last[:D]

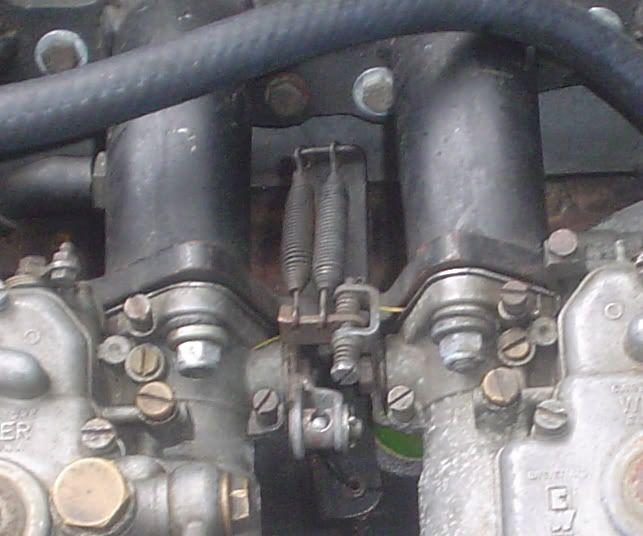

When you set the balance do so with the center screw and then turn the front carbys idle speed screw in a turn or so . This will make it idle. Then adjust the balance screw untill it is right. Now set the idle speed screw and adjust mixtures and adjust idle speed again. Repeat untill it is happy. Do not re adjust the balance screw unless you are sure this has moved.

As you said then wind the other idle speed screw in untill it just takes up. This will reduce the load on the throttle shafts when they are closed.

The emollsion tubes are not so much richer or leaner, more it is about when they make the progression from idle to main cuircut.

One other thing that is vitally important and has caused many of people lots of grief is the choke retaining screws that are underneath the carbies. They must be in place and they must be lock wired , NO EXCEPTIONS. if one of these come loose or fall out the auxillary venturi will turn in its bore and stop the flow of fuel into the barrel. This will cause the car to drop a cylinder. Some times intermitantly.

Dont worry to much about the emolsion tube yet. I am using F16s in the V8. They are really expensive and should only be changed when you are sure they are an issue. Or you have nothing better to do than mess with things that work.[:)]

Cheers Troy