Not my picture, its from a guy on the Dolomite Forum.

Hasbeen wrote:Check the cam follower buckets for straight. They usually turn into a fat lady shape, fat in the middle then rock.

Hasbeen

dursleyman wrote:Ref the engine stand mounting, I prefer this side mounting type so you still have access to the rear seal and flywheel area.

Not my picture, its from a guy on the Dolomite Forum.

Stag76 wrote:Replace it with an EWP...one of the best things you can do to these motors.

dursleyman wrote:Ref the water pump spindle bush that sits down in the block, I had a look on the Dolomite forum and "Jonners" who wrote the book on how to do water pumps says he wasted too much time over the years trying the grease and other methods. His solution is to just use a punch to destroy it and you can then just pull it out with a pair of pliers. Crude but effective apparently.

ps before anyone asks, Jonners is sadly no longer with us, another great source of expertise gone.

Hasbeen wrote:Be careful of the water pump.

After my engine rebuild about 4 years ago, I had an occasional overheating problem. It could even get a bit hot on part of a drive, then behave perfectly most of the day.

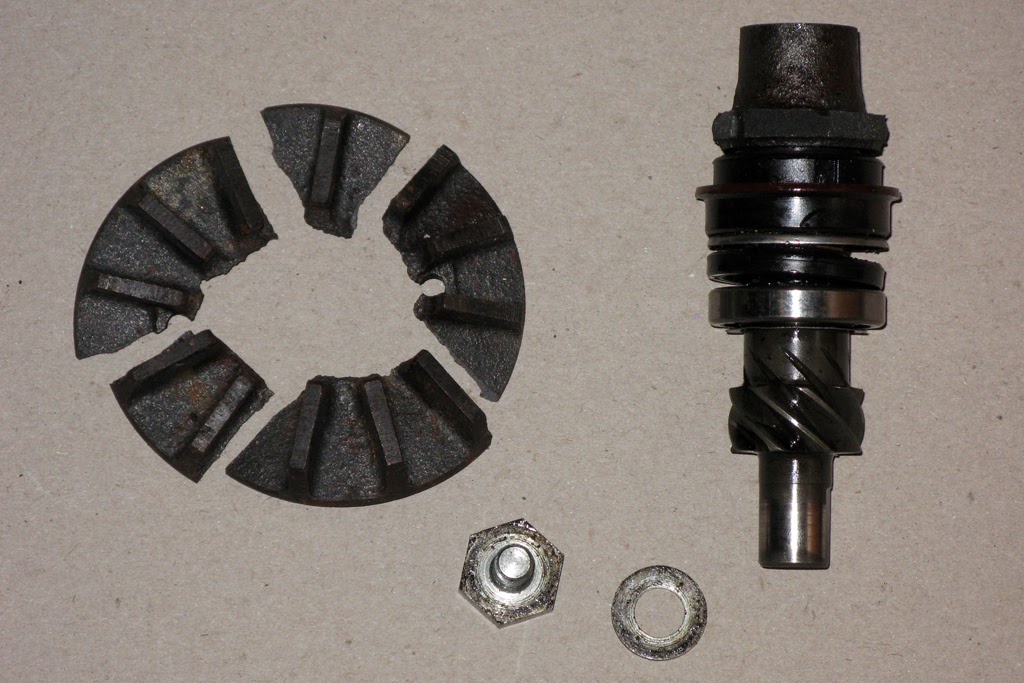

We ultimately found, with great difficulty, that the impellor was not a full tight fit on the shaft, & would sometimes slip, then sometimes not slip. By the appearance of the shaft it would get hot, & or galled, then grip, but not always.

This was one of the most difficult things to diagnose I have ever had.

Hasbeen

Beans wrote:So far I never had to replace the bush, but had to work on the water pump a few times over the years.

Some of the work I did and the problems I encountered, can be addressed through the link below ...

http://tr7beans.blogspot.nl/search/label/Water%20pump

Users browsing this forum: No registered users and 103 guests