After ~60klm on the test run, using mostly very mild throttle, I stopped and fitted the 175 Air Corrector Jets on the F16 Emulsion Tubes. Inspecting the new plugs I thought the mixture looked lean, more so on No 1 & 2 than 3 & 4, so I enriched the mixture screws 1/4 turn on the front carb and 1/8 turn on the rears.

On restart it seemed improved as the bottom end bog was reduced/less prevalent. But on full throttle take off it now had a hesitation and "flutter", most noticable in third gear. It seems like fuel starvation, which I don't understand as the 175 air correctors should have enriched the mixture. Perhaps the fuel pump is not keeping up with demand? I doubt this though as I'm sure I would have experienced the same thing with the other air jets.

I did another 160klm, mosly mild throttle with the odd power take off. When I pulled the plugs No 1 & 2 looked way too rich. No 3 looked a quite lean, No 4 looked a little rich. The discrepancy between No 3 and 4 is confusing as I am confident both were adjusted equally previously. I leaned out (tightened) No 1 & 2 a 1/4 turn (to where they were before), loosened No 3 an 1/4 to enrich and tightend No 4 an 1/8 to lean further.

---

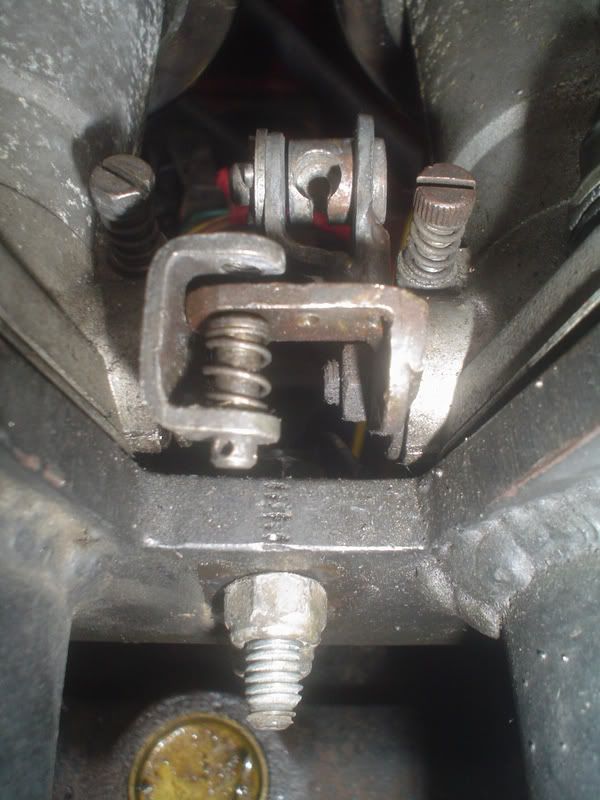

I fabricated a new bracket for the throttle return spring end points, hoping this would provide a better solution to the idle issue. I think there is a problem with the shaft bearings as even with 3 springs stretched way beyond what seems right the tangs are not returning to stop against the idle speed screws when it is hot unless I physically push them up (yet it is now good when cold). Further, their is now so much tension on the accelator it is not so nice to drive. More work required here!

The drive home (another 60klm) was pretty ordinary. [:(]

The low end bog and fast acceleration flutterng had both seemed to have got worse after the mixture changes. [:(!]

I think I need to reset all mixtures and balance again. I'm inclined to order some 180 Air Corrector Jets and fit them as they are between the other two.

Troy, I'm curious about trying the F7 emulsion tubes. Would you recommend changes to the main or air corrector jet to use these?

I'm going to have a closer look at the accel pump next weekend so would value suggestions as to how to check its operation.

---

Something else I'd value advice on is how the crankcase breathing tube from the top rear of the timing cover should be rigged for DCOE setup. With SUs this was plumbed in to ports on the carbs, and hence I assume received a vacuum. On advice from a club member I have run this to the charcoal canister as the Webers did not provide an equivalent pickup. Since doing this I have a small discharge of oil around the Sprint sump dip stick, not major, but suggesting some ring blow by. Opinions welcome.